In the beer industry, bottle labeling plays a crucial role in brand recognition and consumer appeal.

Efficient and accurate labeling methods are essential to maintain product quality and meet market demands.

This article explores three different approaches to bottle labeling, highlighting their advantages and disadvantages.

Among these methods, the fully automated bottle labeling machine emerges as the most efficient and precise option. Let's delve into the details of each method below.

The first method involves manually applying labels to beer bottles.

While this approach may be suitable for small-scale operations or limited production runs,

it has several drawbacks. Manual labeling is time-consuming, labor-intensive, and prone to errors such as misalignment or crooked labels.

Despite its simplicity, this method lacks the efficiency required to meet the demands of a rapidly growing beer market.

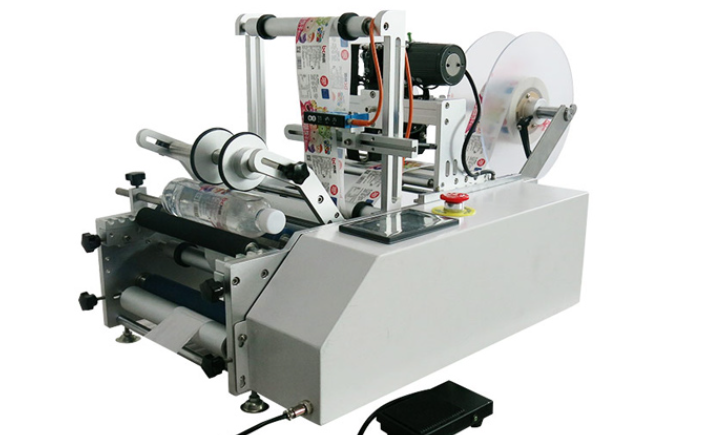

The second method utilizes a semi-automatic labeling machine, which offers an improvement over manual labeling.

In this approach, beer bottles are secured onto the machine's roller seat, and operators simply need to align the labels correctly before initiating the labeling process.

While this method reduces the manual effort required, it still relies on human intervention.

Although more efficient than manual labeling, it falls short of meeting the speed and accuracy needed for large-scale production.

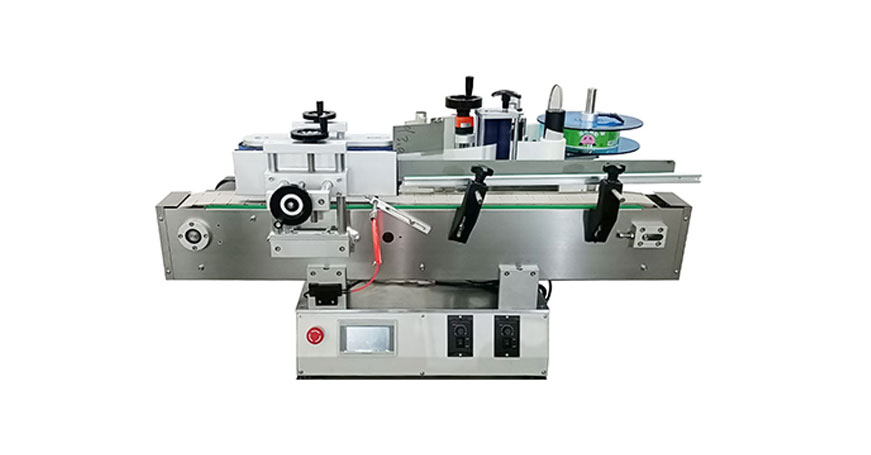

The third method, and the most efficient and precise, is the use of fully automated bottle labeling machines.

With this method, the machine is adjusted and calibrated to the desired specifications.

The beer bottles are then placed on a conveyor belt, and the labeling process begins automatically.

The machine applies the labels accurately and consistently, minimizing the risk of errors.

Human intervention is limited to loading the bottles onto the conveyor and collecting the labeled bottles at the end.

This fully automated approach significantly improves efficiency, productivity, and label placement accuracy. For companies dealing with high production volumes, the fully automated bottle labeling machine is the optimal choice.

In the beer industry, selecting the right bottle labeling method is crucial for maintaining product quality, meeting market demands, and ensuring brand recognition. While manual labeling and semi-automatic labeling machines have their merits, the fully automated bottle labeling machine surpasses them both in terms of efficiency and precision. Investing in a fully automated solution can streamline production processes, increase output, and reduce labor costs. As the beer industry continues to grow, adopting automated technologies such as the fully automated bottle labeling machine becomes imperative for businesses aiming to stay competitive and deliver high-quality products to consumers. Regenerate response

Copyright 2018 ©ZHUONUO WINSKYS TECH CO.,LTD All rights reserved.